How to improve the precision of plastic molds?

Improving the precision of plastic molds can be started from the following aspects:

First, design link

1. Reasonable structural design:

Ensure that the mold structure is stable and can withstand pressure and temperature changes during injection molding.

For example, reinforcement bars, support columns and other structures are used to enhance the rigidity of the mold.

Design a reasonable cooling system to ensure uniform mold temperature and reduce the size change caused by uneven

temperature. The layout of the cooling water channel should fully consider the shape of the mold and the characteristics

of the injection parts to ensure a good cooling effect.

2. Accurate size calculation:

According to the shrinkage rate of plastic material, injection process parameters and other factors, the size of mold cavity

and core is accurately calculated. In the design process, it is necessary to take into account the characteristics of different

plastic materials, as well as the wear of the mold during use, and reserve the appropriate processing allowance.

Second, processing links

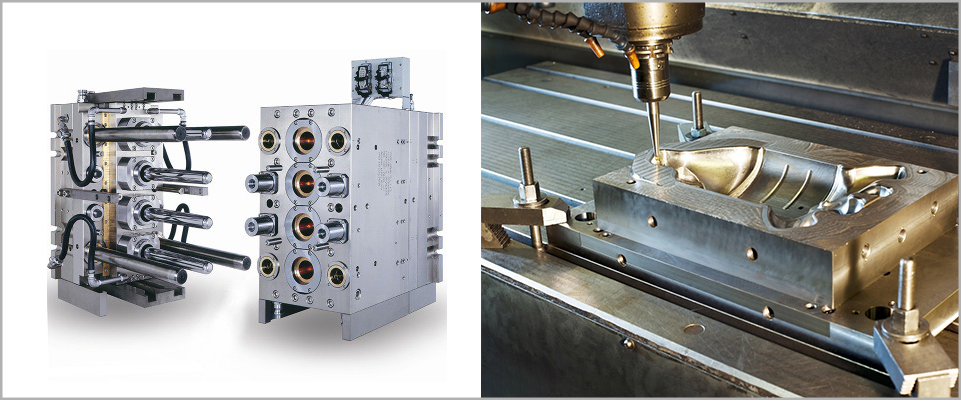

1. Select high-precision processing equipment:

The use of precision CNC machining center, electric discharge machining machine, wire cutting machine and other

equipment to ensure the machining accuracy of mold parts. These devices have high-resolution control systems and precise

transmission mechanisms, enabling high-precision machining.

Regular maintenance and calibration of the processing equipment to ensure the accuracy and stability of the equipment.

2. Optimize the processing technology:

Reasonable machining sequence and tool path are adopted to reduce machining errors. For example, rough machining is

carried out first to remove most of the surplus, and then semi-finishing and finishing are carried out to gradually improve

the processing accuracy.

Control machining parameters, such as cutting speed, feed rate, cutting depth, etc., to obtain the best machined surface

quality and dimensional accuracy. For high hardness mold materials, low speed and small feed can be used to reduce tool

wear and processing deformation.

3. Precision measurement and testing:

Use high-precision measuring tools, such as coordinate measuring instrument, optical projector, etc., to inspect mold parts.

In the process of processing, it is necessary to carry out multiple measurements to discover and correct processing errors in time.

Establish a strict quality control system to comprehensively test the size, shape and surface roughness of the mold parts to

ensure that they meet the design requirements.

Third, the assembly link

1. Cleaning and inspection:

Before assembly, mold parts are thoroughly cleaned to remove processing residues and oil stains. Check the size, shape and

surface quality of the parts to ensure that they meet the assembly requirements.

Fine machining and grinding of important matching parts to improve the matching accuracy. For example, the matching gap

between the core and the cavity should be controlled within a reasonable range to ensure the dimensional accuracy of the

injection parts.

2. Precise assembly process:

The use of professional assembly tools and equipment to ensure that the mold parts installation position is accurate. For example,

tools such as positioning pins and jigs are used to ensure the relative position accuracy of parts.

Assemble according to the assembly sequence and process requirements, avoid forced assembly and beating. During the assembly

process, attention should be paid to checking the parameters such as the matching gap, parallelism and perpendicularity between

the parts to ensure the overall accuracy of the mold.

3. Debugging and optimization:

After the mold assembly is completed, debug and test the mold. By adjusting injection molding process parameters, mold

temperature, pressure and other factors, optimize the performance and accuracy of the mold.

Analyze and solve the problems in the process of mold testing, such as size deviation, surface defects, etc. According to the test

results, the necessary adjustment and improvement of the mold are carried out to improve the precision of the mold.

Fourth, material selection

1. High quality die steel:

Select die steel with high hardness, high wear resistance, good thermal stability and machining performance. High-quality die

steel can ensure that the mold in the long-term use of the process to maintain dimensional stability, reduce wear and deformation.

According to different requirements of injection parts and production batches, choose the appropriate die steel material.

For example, for high-precision and high-yield injection parts, imported high-quality die steel can be selected.

2. Standard accessories:

Choose standard mold accessories, such as guide post, guide sleeve, thimble, etc. The accuracy and quality of standard accessories

are guaranteed, and the overall assembly accuracy of the mold can be improved.

Check and replace mold parts regularly to ensure good performance.

Fifth. Personnel training and management

1. Professional technical training:

Professional technical training for mold design, processing, assembly and other links of the staff to improve their skill level and

quality awareness. The training content includes the principle of mold design, processing technology, assembly skills, quality

control and so on

Encourage employees to continue to learn and master new technologies and methods to improve the overall level of mold

manufacturing.

2. Strict quality management:

Establish a perfect quality management system, and strictly control the quality of all aspects of mold manufacturing. Develop

quality standards and inspection specifications, and strengthen the inspection of raw materials, processing processes, assembly

processes and finished products.

Timely analysis and treatment of quality problems, take effective corrective and preventive measures to avoid the recurrence of

problems.