What are medical plastics and commonly used products?

Medical plastics are a class of plastic materials used in the medical field, with a variety of characteristics and a wide range of

applications, the following are some important knowledge about medical plastics:

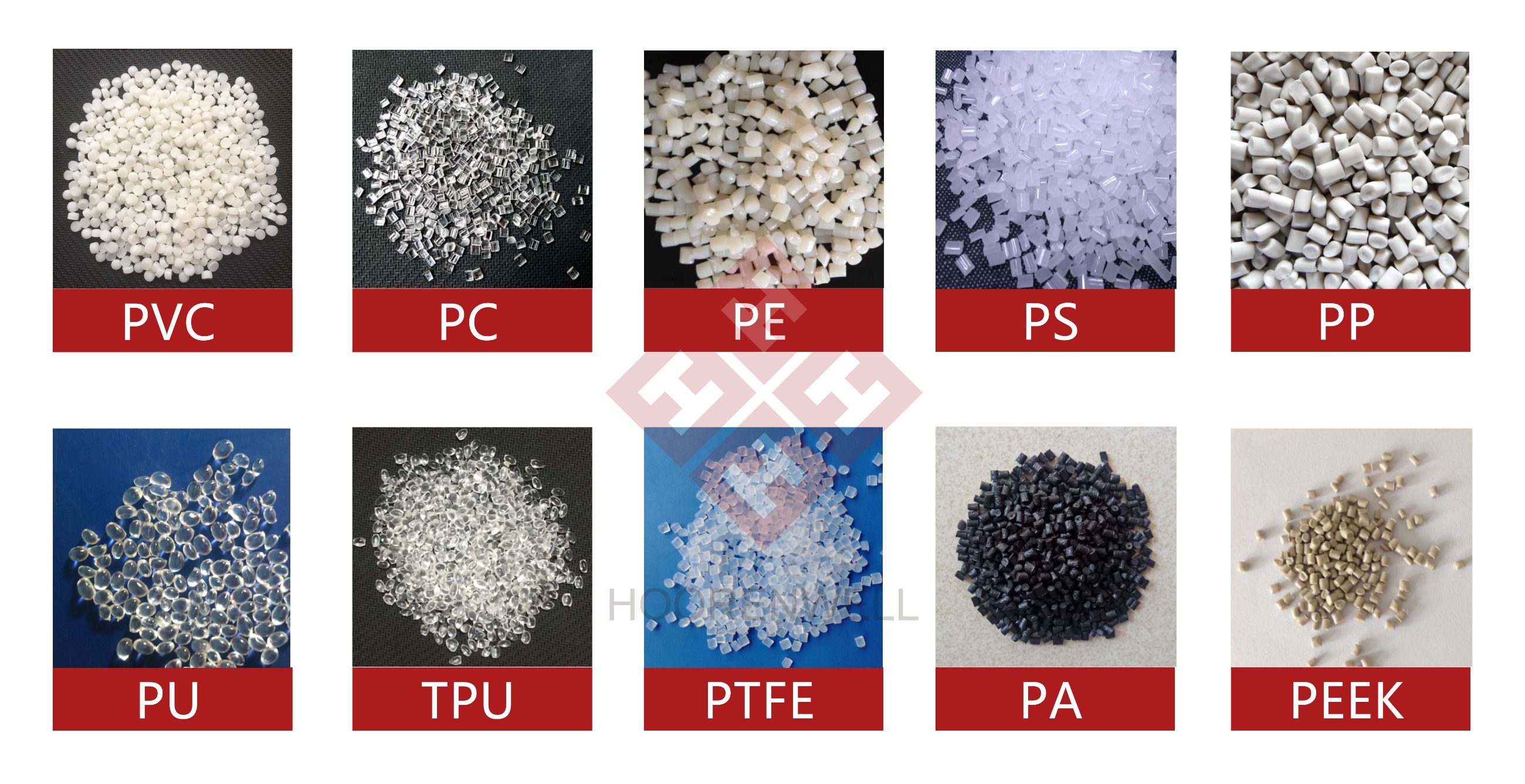

1. Types and characteristics of commonly used medical plastics:

Polyvinyl chloride (PVC) :

Features: low cost, wide application range, easy processing, with good chemical resistance, but poor thermal stability.

Uses: Commonly used in the production of blood bags, various intubation, catheter, pipeline, artificial peritoneum and so on.

Due to its softness and machinability, it is suitable for medical devices that need to bend and deform.

Polycarbonate (PC) :

Features: It has the characteristics of toughness, strength, rigidity and good heat resistance steam toxicity, high transparency.

However, the material is prone to stress cracking.

Uses: It can be used in the manufacture of hemodialysis filters, various shells, connectors, surgical tool handles, oxygen tanks,

needle-free injection systems, perfusion instruments, blood centrifuge bowls and pistons, etc. Its high transparency makes it

widely used in some medical devices that need to observe internal conditions.

Polyethylene (PE) :

Features: High chemical stability, good biocompatibility, but not easy to bond.

Classification and Use:

1. Low density polyethylene (LDPE) : often used in medical packaging and intravenous injection containers, with good softness

and transparency.

2. High density polyethylene (HDPE) : can be used for artificial urethra, artificial lung, artificial trachea, artificial throat, artificial

kidney, artificial bone, orthopaedic repair materials, etc., with high hardness and strength.

3. Ultra-high molecular weight polyethylene (UHMWPE) : used for artificial lungs, artificial joints, etc., with high impact strength,

low friction, stress cracking resistance and better energy absorption characteristics.

Polystyrene (PS) :

Features: low cost, low density, transparent, stable size, radiation resistance (disinfection). The texture is hard and brittle, and has

a high coefficient of thermal expansion.

Uses: Crystalline polystyrene can be used to make laboratory utensils, petri dishes and tissue culture dishes, respiratory equipment

and suction tanks, etc. High impact polystyrene can be used in catheter plates, heart pumps, dural discs, respiratory equipment

and suction tanks.

Polypropylene (PP) :

Features: non-toxic, tasteless, with good mechanical properties, chemical stability and heat resistance, good insulation, low water

absorption, good solvent resistance, oil resistance, weak acid resistance, weak alkali resistance, good molding, no environmental

stress cracking problems. However, its molding shrinkage is large, the surface inertia is large, and it is difficult to print and bond.

Uses: Common in disposable syringes, connectors, transparent plastic covers, straws, parenteral injection nutrition packaging,

dialysis film, etc.

Polyurethane (PU) ? :

Features: Excellent physical properties, good chemical stability, good biocompatibility, strong wear resistance, smooth surface.

Uses: Used in the medical field for artificial heart assistance devices, catheters, artificial joint pads, etc.

Thermoplastic polyurethane (TPU) :

Features: It has good transparency, high strength and tear performance, good chemical resistance and wear resistance, wide

hardness range, smooth surface, anti-fungal and microbial resistance, and high water resistance.

Uses: It can be used for medical catheter, oxygen mask, artificial heart, drug release equipment, IV connector, rubber bag of blood

pressure monitor, wound wrap for drug delivery, etc.

Polytetrafluoroethylene (PTFE) :

Features: high crystallinity, small friction coefficient, good heat resistance, high chemical stability, strong acid and alkali and various

organic solvents do not work with it, has good biological compatibility, blood adaptability, no damage to human physiology,

no adverse reactions implanted in the body, can be sterilized at high temperature.

Uses: It can be used in the manufacture of veins, heart membrane, endoscope, forceps catheter, trachea, other tubes, bottles,

filter cloth and other medical equipment.

Polyamide (PA) :

Features: With flexibility, bending resistance, high toughness is not easy to break, chemical resistance and wear resistance is good,

does not release any harmful substances to the human body, so does not cause skin or tissue inflammation.

Usage: Often used in the production of hoses, connectors, adapters, pistons and so on.

Polyether ether ketone (PEEK) :

Features: heat resistance, wear resistance, fatigue resistance, radiation resistance, corrosion resistance, hydrolysis resistance,

light weight, good self-lubrication, good processing performance, can withstand repeated autoclaving.

Uses: Can replace metal for surgical and dental instruments, instead of titanium alloy to make artificial bone, has advantages in

minimally invasive surgery, will not produce artifacts.

Second, performance requirements:

1. Chemical stability: Medical plastics need to have good chemical stability, in contact with drugs or in the internal environment

of the human body, no chemical reaction will occur, and no harmful substances will be released to ensure the safety of patients.

2. Biosafety: It is non-toxic and harmless to human body, does not cause toxicity and damage to tissues and organs, and does

not cause adverse biological reactions such as immune rejection.

3. Physical and mechanical properties: According to different application scenarios, it is necessary to have appropriate strength,

elasticity, toughness, hardness and other physical and mechanical properties to meet the requirements of medical devices. For

example, artificial joint materials need to have high strength and wear resistance, while catheter materials need to have a certain

degree of flexibility and bendability.

4. Processing performance: easy to process into various shapes and sizes of products, can adapt to different production processes,

such as injection molding, extrusion, blow molding and so on.

5. Sterilization adaptability: It can withstand various sterilization methods, such as high temperature autoclave sterilization, radiation

sterilization, ethylene oxide sterilization, etc., and the performance will not be significantly affected after sterilization.

Third. Application fields:

1. Medical devices: Medical plastic is an important material for the manufacture of medical devices, such as disposable infusion

sets, syringes, catheters, intubations and other disposable medical plastic devices. The use of medical plastic for these devices can

reduce costs, ease of use, and ensure health and safety, reducing the risk of cross-infection. In addition, there are various medical

plastic products, such as tracheal intubation, airway, vascular intubation, puncture cannula, etc., as well as instruments for repair,

care, physiotherapy and diagnosis.

2. Medical packaging: Used for pharmaceutical packaging, medical consumables packaging, etc. For example, medical packaging

materials such as eyedrop medicine bottles, oral liquid bottles, PVC plastic bottles, and low-density polyethylene ointment tubes

need to have good barrier property, sealing property and chemical stability to ensure the quality and safety of drugs.

Four. Development trend:

1. High performance: With the continuous development of medical technology, the performance requirements for medical plastics

are becoming higher and higher. In the future, medical plastics will continue to develop in the direction of high performance, such

as improving strength, wear resistance, fatigue resistance, biocompatibility, etc., to meet the needs of more complex medical

applications.

2. Green environmental protection: The improvement of environmental awareness has promoted the development of medical plastics

in the direction of green environmental protection. Developing degradable medical plastics, reducing pollution to the environment,

and improving the recycling rate of medical plastics will be the future development trend.

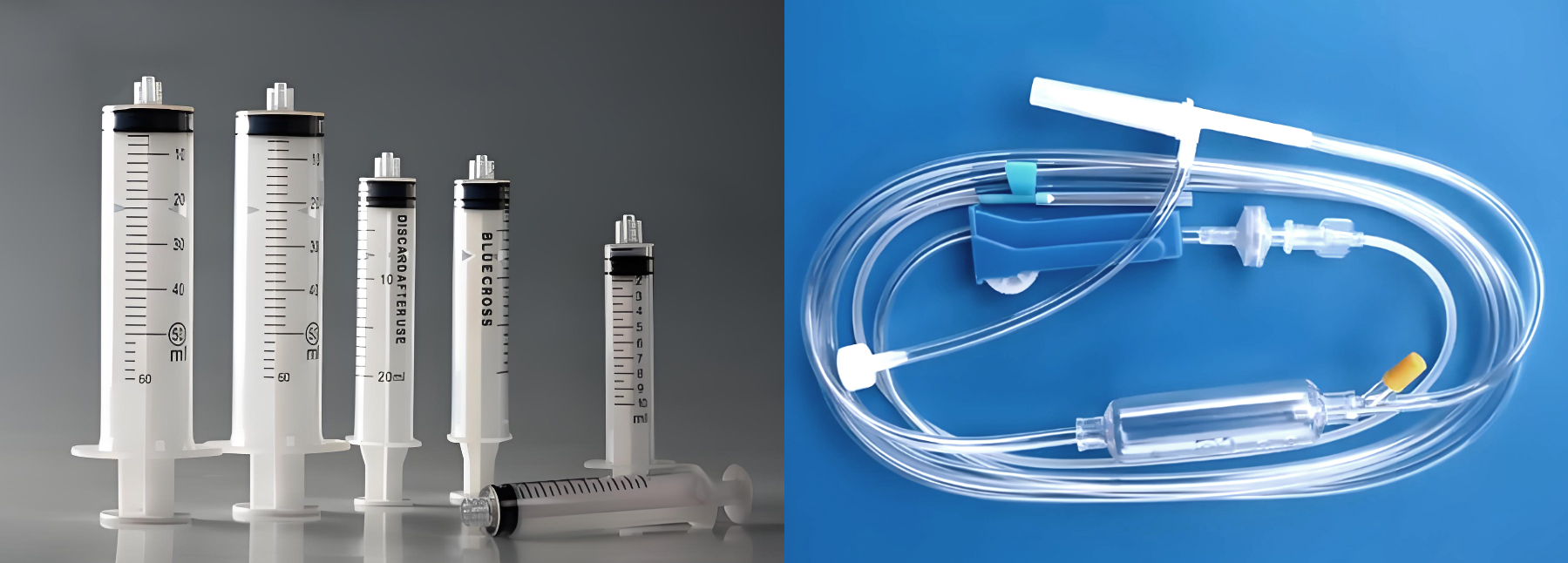

Fifth. Commonly used products of medical plastics include:

1. Medical syringe

Medical syringes are one of the medical devices commonly used by medical institutions and individual consumers, and most

medical syringes are made of plastic. Medical syringes can be divided into disposable syringes and reusable syringes, disposable

syringes are widely used in hospitals and home medicine. The materials of medical syringes mainly include polyolefin materials,

PVC materials, PC materials, PP materials, etc.

2. Infusion set

Infusion sets are also commonly used medical devices in medical institutions and individual consumers. Infusion set is composed

of plastic pipes and plastic accessories, the main materials are PVC materials, PP materials and so on. The capacity of the infusion

set is generally 50ml, 100ml, 250ml, etc.

3. Medical gloves

Medical gloves are commonly used medical supplies by medical staff, which mainly protect the skin of the hands of medical staff

to avoid infection with infectious diseases. Commonly used medical glove materials are latex materials, nitrile materials and so on.

In short, a variety of modern medical equipment and supplies, many are made of plastic, the wide application of plastic products

makes the quality of medical supplies more stable, safe, but also provides reliable support for medical security.