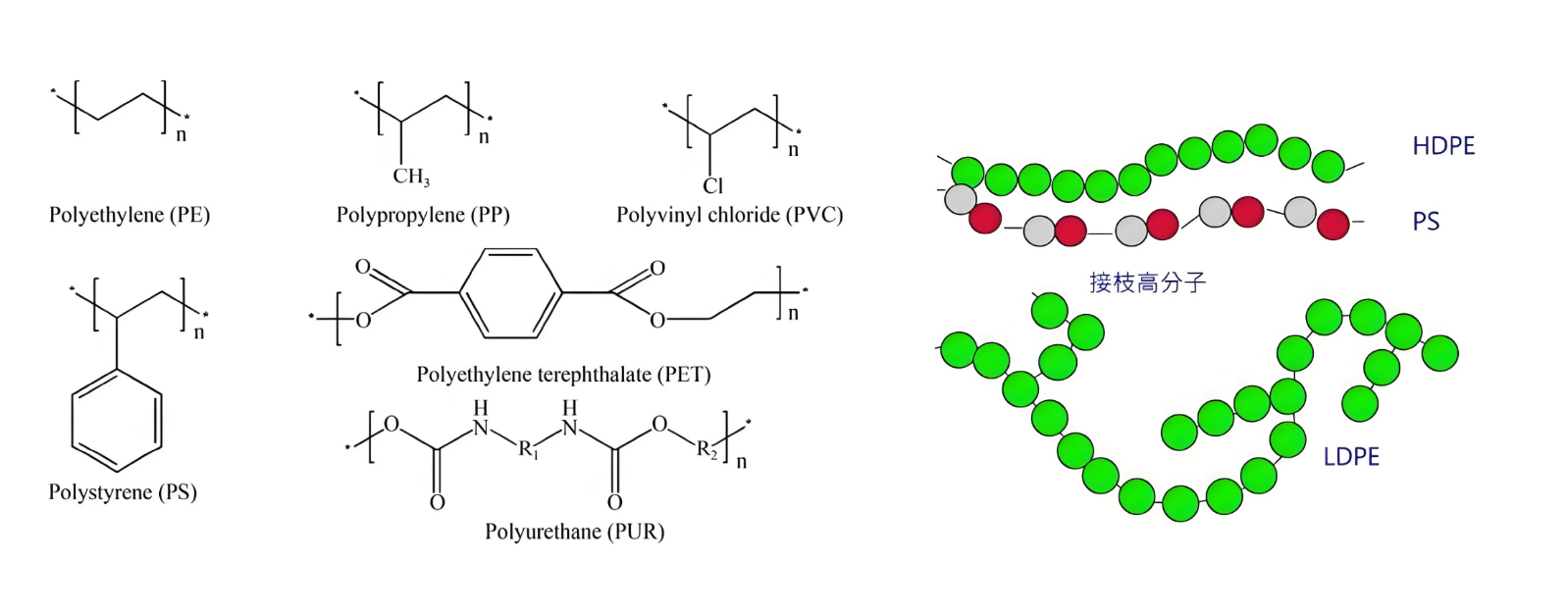

Plastics, as polymer materials, consist of numerous polymer chains with diverse characteristics:

Chain Structure: Molecular chains can be linear, branched, or cross - linked. Linear chains move more freely. Branched chains have increased steric hindrance and reduced flexibility. Cross - linked chains form a rigid network structure, limiting their mobility.

Chain Length and Molecular Weight Distribution: Varying chain lengths and molecular weight distributions exist. Longer chains require more force to orient and significantly impact material properties like strength and toughness.

Chemical Structure Characteristics: Features such as the type of chemical groups on the chain, their arrangement, and interaction forces are crucial. Polar - group - containing chains may have strong intermolecular forces, affecting their initial state and orientation under external forces.

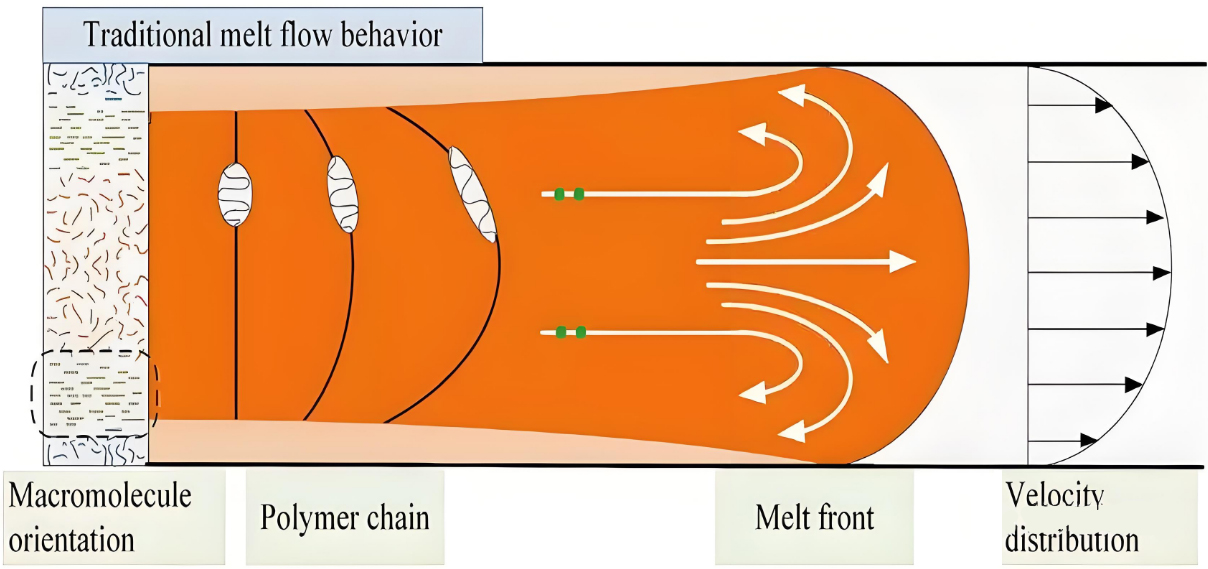

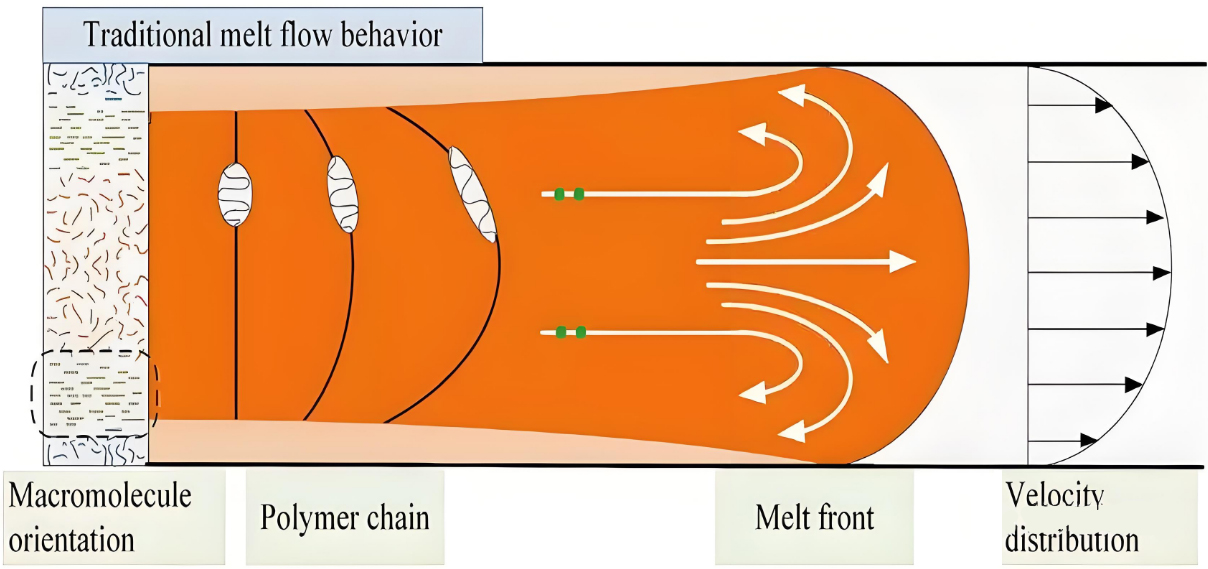

Shear Force Generation Mechanism: In plastic processing (e.g., injection molding, extrusion, calendering), the melt experiences shear force during flow. In injection molding, the melt is pushed from the cylinder through the nozzle into the mold's pouring system. Shear force forms due to relative movement between the melt and the flow - channel wall. In extrusion, the screw's rotation and the die also create shear effects.

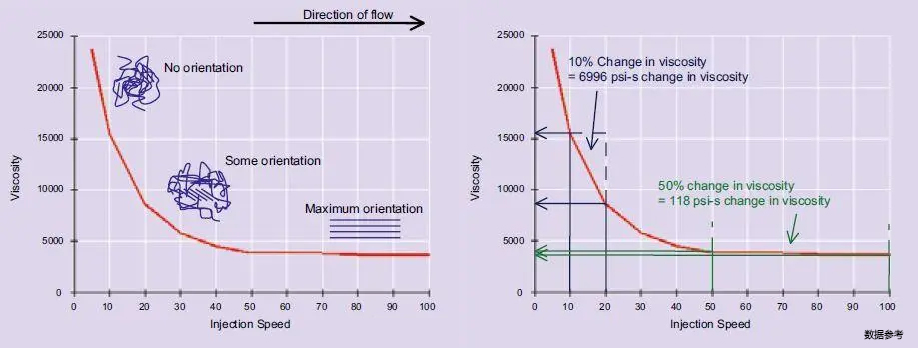

Molecular Chain Response Process: When sheared, disordered, coiled molecular chains start to respond. Chains near the flow - channel wall, most affected by shear, straighten and stretch along the shear direction. As the distance from the wall increases, the shear force weakens, but still causes chain alignment, with a lower degree of orientation. This orientation occurs gradually under continuous shear force, forming a gradient distribution from the wall to the center.

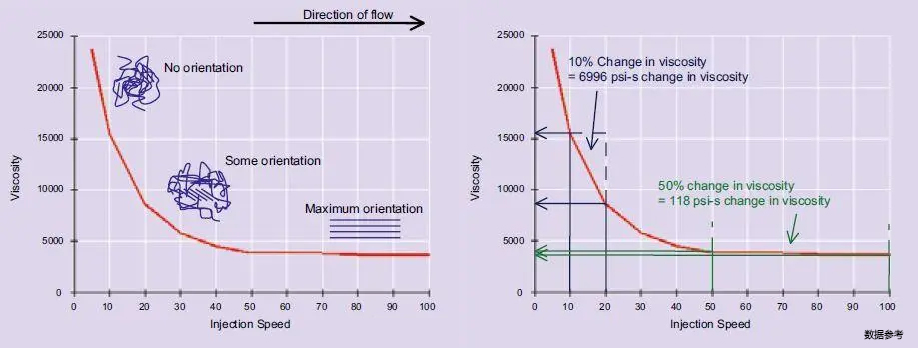

Influencing Factors: Shear rate significantly impacts orientation. Higher shear rates lead to faster and more complete orientation but may cause melt instability and defects. Flow - path geometry (diameter, roughness) and plastic viscosity also affect molecular - chain orientation.

Tensile Force Source and Action Scenario: In processes like blow molding and fiber spinning, tensile force promotes molecular - chain orientation. In blow molding, the plastic billet is stretched by compressed air. In fiber spinning, the melt extruded from the spinneret is rapidly stretched.

Factors Affecting the Degree of Orientation: Tensile ratio and rate are key. A higher tensile ratio enhances orientation, and a faster tensile rate helps form a highly oriented structure. However, a too - fast rate may cause material fracture. Temperature and the material's elastic modulus also influence orientation. Higher temperatures make chains easier to stretch, and the elastic modulus is related to the orientation change during stretching.

At high processing temperatures, molecular - chain thermal movement intensifies, making it easier for chains to overcome internal friction and intermolecular forces and orient along external - force directions. For example, in injection molding, increasing the cylinder temperature improves melt flow and molecular - chain orientation. But if the temperature is too high, the formed orientation may relax due to excessive thermal motion, reducing the orientation degree and affecting product performance.

Low temperatures inhibit molecular - chain thermal movement. Even with external forces, chains struggle to adjust to the force direction. In extrusion, if the cylinder temperature is too low, the melt viscosity increases, fluidity worsens, and molecular - chain orientation in the flow channel is sub - optimal, leading to non - uniform product internal structures and weak anisotropy. Choosing an appropriate temperature range, considering plastic type, process characteristics, and product requirements, is essential for good orientation.

For crystalline plastics, the flow - induced orientation impacts crystallization. The molecular - chain orientation direction often becomes the preferred crystal - growth direction. The ordered chain arrangement in the orientation state facilitates nucleation and crystal growth, resulting in an anisotropic crystalline structure that affects product mechanical and optical properties.

Conversely, crystal formation limits or guides further molecular - chain orientation. Once crystals form, the molecular chains in the crystalline regions are fixed, restricting new orientation. The orientation of uncrystallized chains around the crystals may be guided by the crystals, and this interaction shapes the final microstructure and properties of plastic products.

After flow and orientation, the molecular - chain orientation can be "frozen" by rapid cooling. In injection molding, quick mold cooling reduces the melt temperature, weakening molecular - chain thermal movement and fixing the orientation. Products with frozen orientation show performance anisotropy, such as higher tensile strength and modulus along the orientation direction and optical birefringence.

Without timely cooling or when exposed to high temperatures and long - term external forces, the molecular - chain orientation may relax. Thermal motion and external forces cause the ordered chains to become disordered, reducing the orientation degree. For example, plastic products in a high - temperature environment for a long time may experience a weakening of their orientation - related strength advantage and reduced performance anisotropy, affecting their use and lifespan.

In summary, plastic orientation in flow is a complex, multi - factor process involving molecular - chain characteristics, external forces, temperature, crystallization, and orientation - state changes. These factors interact and jointly determine the performance and quality of plastic products.