Plastic gear injection molding process and material analysis

Development Trends of Plastic Gears

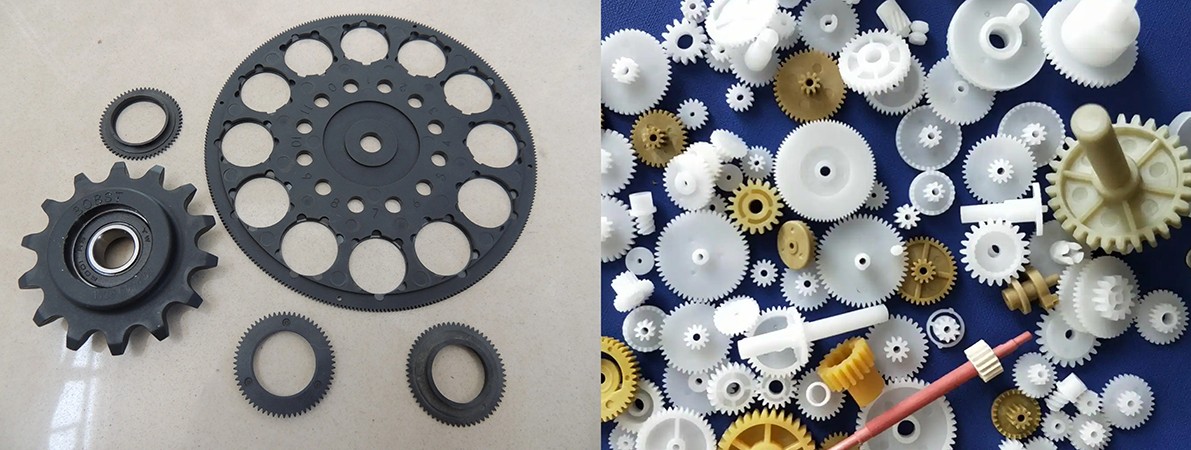

Plastic gears are advancing towards larger sizes, more complex geometries, and higher strength. High - performance resins and long

glass fiber - filled composites drive this progress. Over 50 years, they've evolved from new to key industrial materials, now applied in diverse fields like autos, watches, and missiles for torque and motion transmission. New applications are emerging.

Applications in the Automotive Industry

The auto industry is the fastest - growing area for plastic gears. Car manufacturers seek motor - gear - based auxiliary systems, leading to plastic gear use in power windows, brakes, and more.

Expansion of Application Areas

Plastic power gears' applications are expanding. They replace metal gears in large - size applications like washing machine drives and are used in HVAC, fluid facilities, and military equipment.

Large - sized and High - strength Plastic Gears

Plastic gear molding advantages enable larger, high - precision, and high - strength gears. But designing optimal gear configurations is hard, with strict precision demands. Complex molding operations may be needed, and core teeth can reduce shrinkage. Molding high - precision products is a challenge.

Control Difficulties

High - precision gear tolerances are strict. Molding experts use advanced machines and sensors to control temperature, pressure, etc. Manufacturers need professional inspection tools. Molders must control the environment, train staff, and ensure process consistency as gear size is sensitive to temperature changes.

Important Molding and Cooling Steps

Precision gear processing requires attention to detail. Molds usually have few cavities, and gears are best injected from a single central gate. Controlling factors like temperature, pressure, and cooling is crucial for consistent, high - quality products.

New Processes and Resins

New molding methods like two - shot molding are being developed. Consideration of gear structure and various engineering thermoplastics, each with unique properties, offers more choices for gear manufacturing.

Advantages of Using Plastic Gears

Plastic gears have design, cost, and performance advantages over metal gears. They can be molded into complex shapes, are quieter, cheaper, lighter, and more corrosion - resistant. They can also absorb impact and distribute load better.

Reinforcement of Materials

Fibers and fillers enhance resin properties. For example, short and long glass fiber fillers improve acetal copolymer's strength, hardness, and other properties, making long glass fiber - reinforced materials attractive for large - sized gear applications.