Multi - color multi - material injection molding process is a manufacturing process or production unit that combines multiple plastics into multi - functional parts. This technology uses various materials for injection molding production. It combines the characteristics of different materials during the molding process through assembly or other suitable bonding methods, enhancing product functionality and aesthetics. It offers significant saving potential and new design possibilities for product manufacturing.

The materials used in multi - color injection molding must meet two basic compatibility conditions: adhesive compatibility and processing compatibility.

Injection Unit: Structures such as parallel and same - direction, parallel opposite - direction, horizontal and vertical L - type, Y - type single - cylinder injection structures can be used.

Mixed Nozzle: Special nozzles like pattern, wave, flow mark, gradient, and sandwich types can be selected.

Clamping Die: Mechanisms such as standard type, vertical rotating disk type, horizontal rotating disk type, rotating shaft type, and manipulator rotation type can be chosen.

One of the key factors in multi - color injection molding is the variability of the computer control program. Even for the same type of multi - color products, different mold designs require different electronic control procedures.

With the development of the national economy, the automotive industry has become a pillar industry. Currently, the rapid growth of the automotive industry has led to increasingly higher requirements for automotive lighting. The quality of automotive lighting is crucial for driving safety. Thus, regulations in countries around the world have strict requirements for it. The lamp design should not only meet regulatory safety requirements but also other criteria. It should be integrated with the overall car appearance, be beautiful and practical, and comply with aerodynamic requirements to ensure driver and passenger comfort and convenience. As a result, headlight design technology is evolving with the development of the automotive industry.

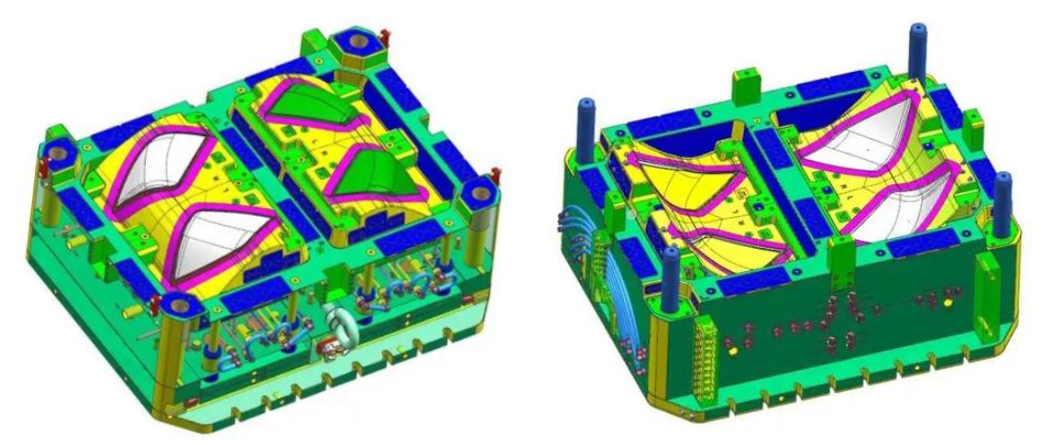

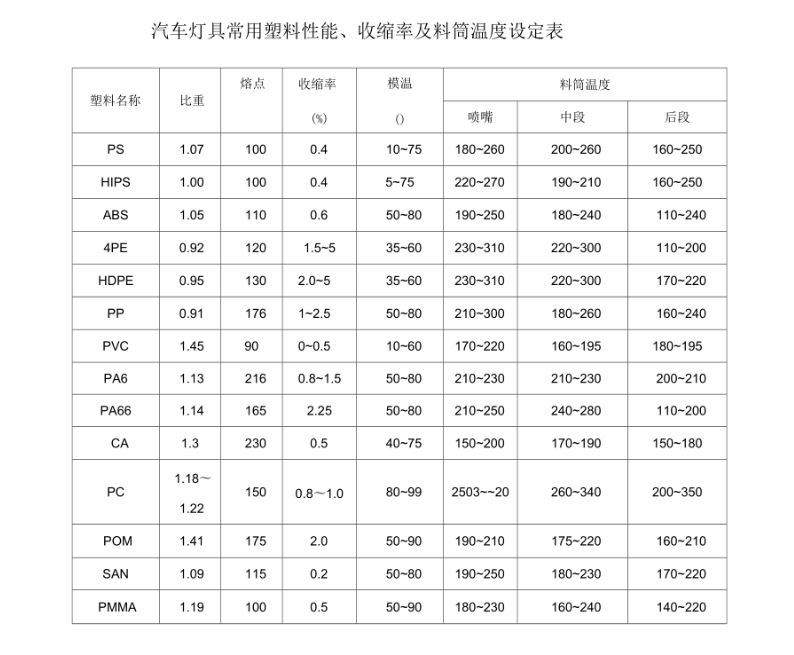

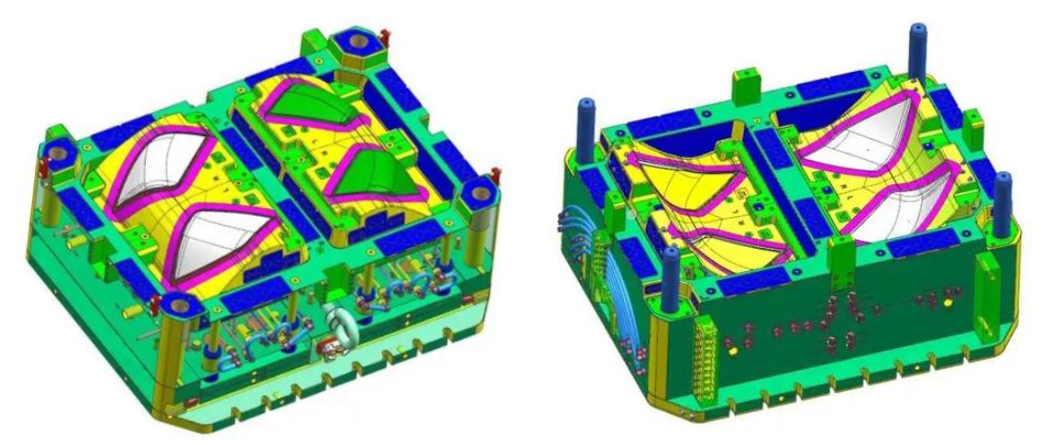

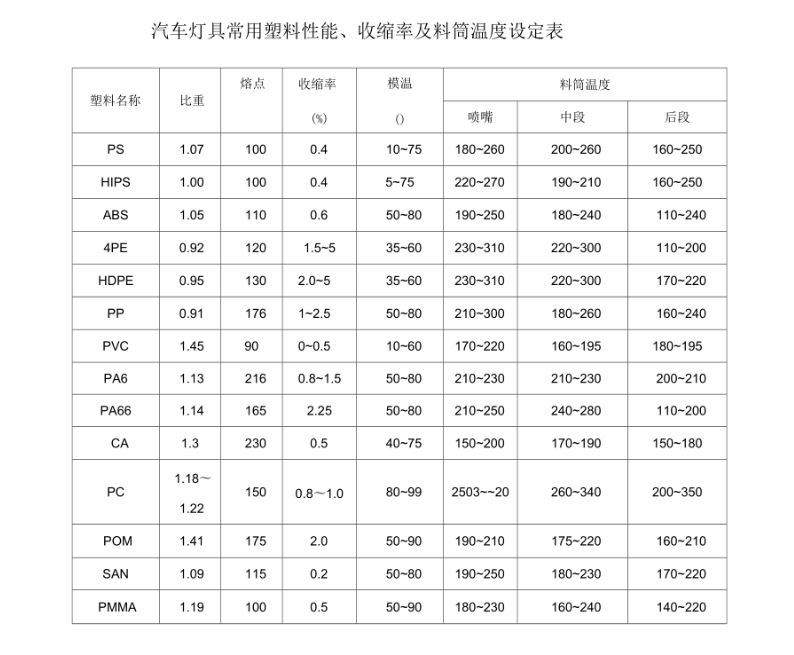

Lights generally consist of a base and a lamp shell. The base material is usually a thermosetting material - BMC (group molding plastic). The lamp shell can be processed from materials such as PMMA, PP, and ABS, usually in two or three colors.

In the two - color lamp production process, special attention should be paid to the injection part of the two - color injection molding machine. The center distance of the two screws should match the center distance of the two - color mold.

Control Unit Response: Long switching point, noise interference, unstable command output, and temperature instability.

Oil Pressure System Noise: Pressure instability, valve positioning characteristics, hysteresis, and changes in oil pipe damping.

Mechanical System Differences: Oil seal internal drainage, damping, friction differences, screw check valve positioning, and check effect.

Uneven Plasticizing: Differences in plasticizing characteristics.

Mold Temperature Control.

Screw idling without feeding.

The torque required for the screw is too large to rotate.

Incomplete plastic melting.

Unstable screw measurement.

Uneven plastic mixing.

Easy temperature rise of low - temperature molding plastic.

Bubbles in the molding product.

The molding product is prone to spitting black and yellow.

The screw is prone to corrosion, wear, and has a short service life.

The plastic plasticizing screw tube group is the core component of the injection molding machine, responsible for functions such as transportation, melting, mixing, and metering of plastic raw materials. Thus, the plastic plasticizing screw is closely related to the quality of the molding product. The main purposes of improving the plasticizing screw are:

L/D ratio: 21 - 23.

The surface roughness should be extremely smooth to avoid material accumulation.

Increase the corrosion - resistance of the plating thickness.

Compression ratio: 2.3, feeding section: about 50%, compression section: about 30%, metering section: about 20%.

Scorch: Reduce the injection pressure, use multi - stage deceleration injection, and apply mold vacuum.

Silver Grain: Thoroughly dry plastic particles, increase the back pressure, reduce the melting temperature, and lower the injection rate.

Bubbles: Increase the back pressure, reduce the melting temperature, use a dehumidifying dryer, and enlarge the size of the gate or runner.

Combination Line: Increase the melt temperature, raise the filling speed, enhance exhaust and die temperature.

Raw Edge: Increase the clamping force, reduce the filling pressure, and lower the melt temperature.

Shrinkage: Optimize thickness design, increase the pressure and time, and replace the check valve.