The basic idea of injection molding machine maintenance work

2024-12-13 15:02:04

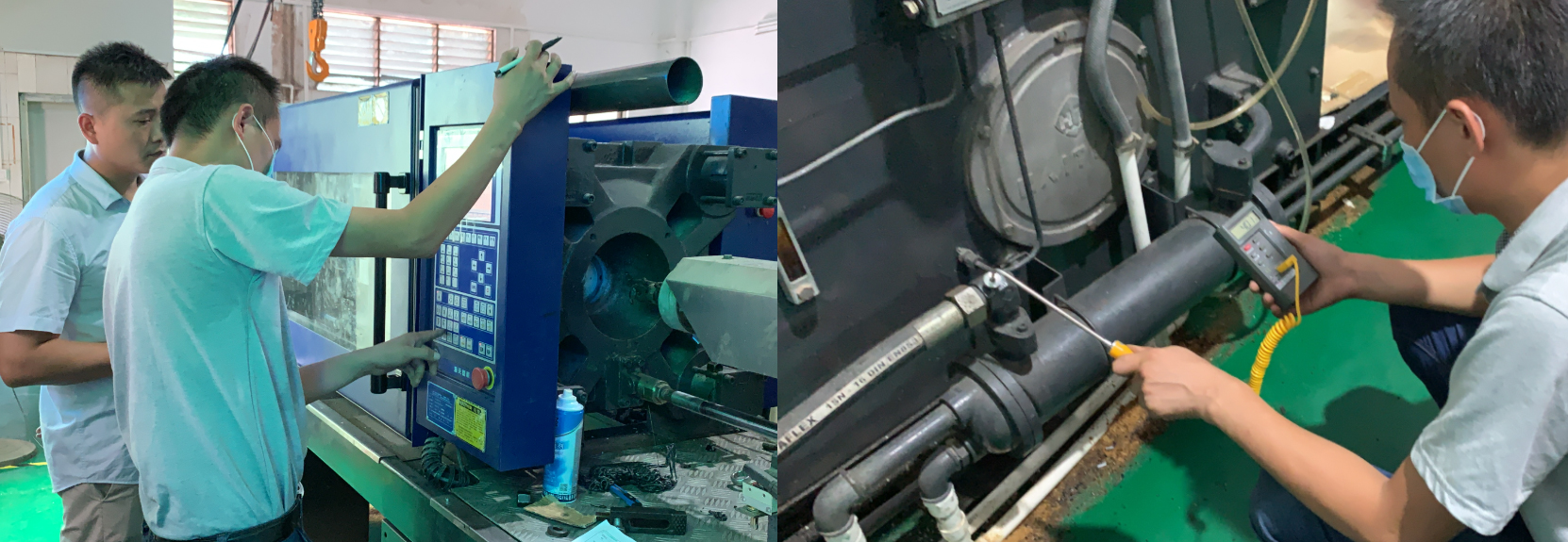

injection molding machine maintenance work

1. Core of Maintenance Work

Injection molding machine maintenance centers on fault judgment and treatment. It demands knowledge in mechanical, hydraulic, and electrical maintenance. Maintenance workers need to understand the machine's operation manual, be familiar with its mechanical parts, circuits, and oil circuits, and know normal and abnormal working states to avoid misjudgment.

2. Importance of Operation and Debugging Knowledge

3. Maintenance Principles and Information Collection

4. Basic Ideas of Maintenance Work

4.1 Fault Phenomenon Collection and Analysis

4.1.1 Communication with Operators

4.1.2 Observation of Fault Phenomena

4.2 Initial Fault Scope Determination

4.2.1 Mechanical System

4.2.2 Hydraulic System

4.2.3 Electrical System

Check the power supply, electrical lines in the control cabinet, and detection elements such as sensors.

4.3 Troubleshooting and Repair

4.3.1 Screening Plan

4.3.2 Tools and Spare Parts Preparation

4.3.3 Fault Repair

4.4 Test and Verification after Maintenance

4.4.1 No - load Test

4.4.2 Load Test

4.4.3 Data Recording and Summary